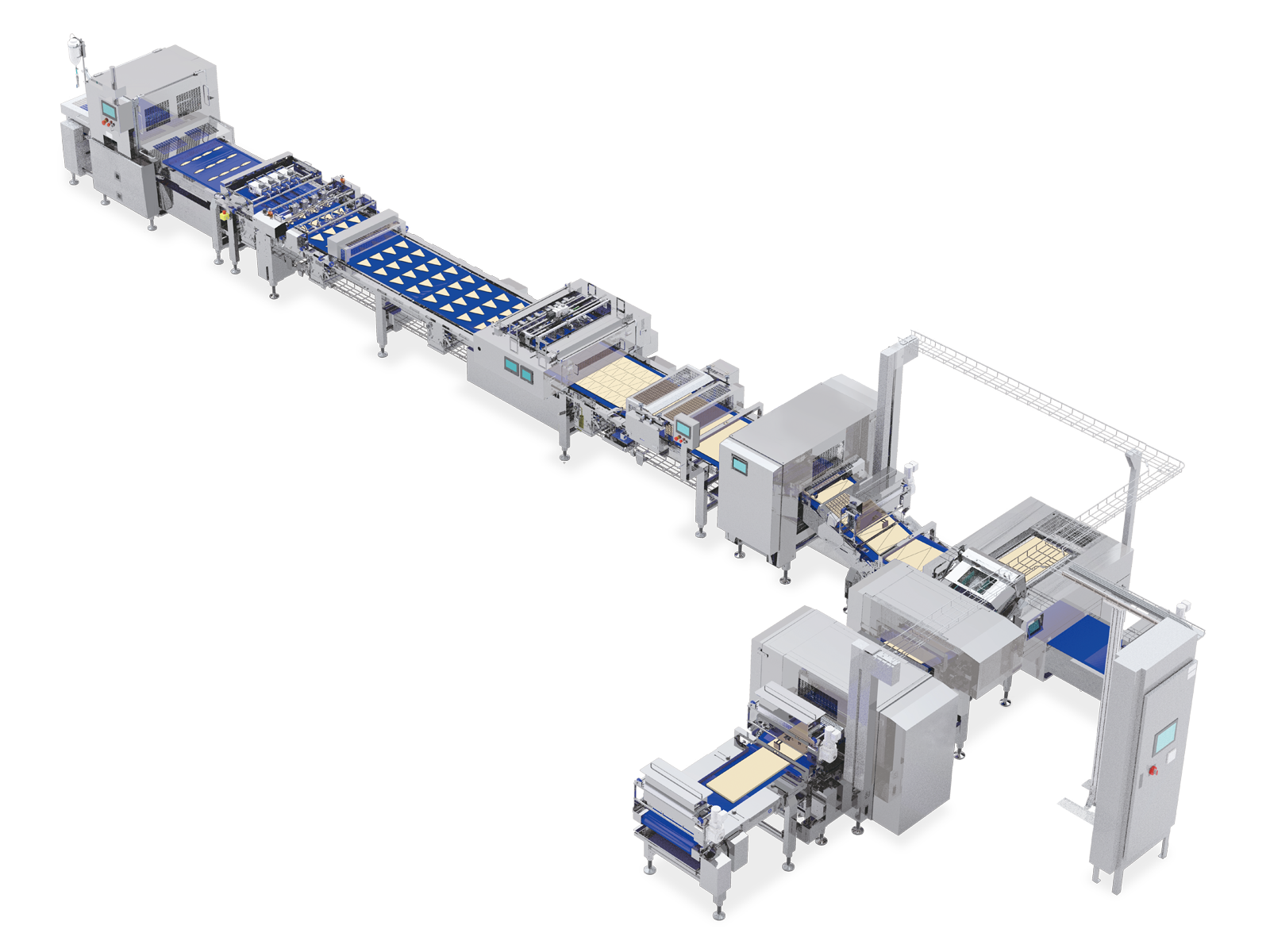

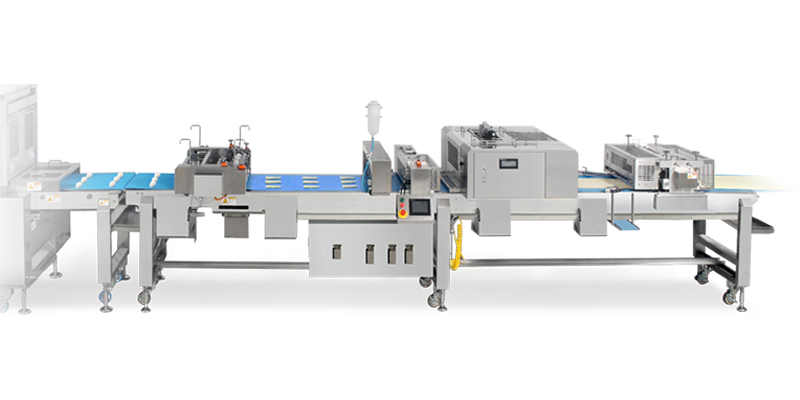

HM Pastry Line

Booking Conveyor

Manually supplies the pastry dough.

New Multi-Stretcher (#1)

Stretches the supplied dough into sheets without damaging it.

New Parallel Piler

Folds the dough to create layers.

New Multi-Stretcher (#2)

Stretches the folded dough into a thin sheet.

Variety Make-up Table

Combining various optional attachments allows for the stretched dough sheets to be automatically shaped into a variety of products.

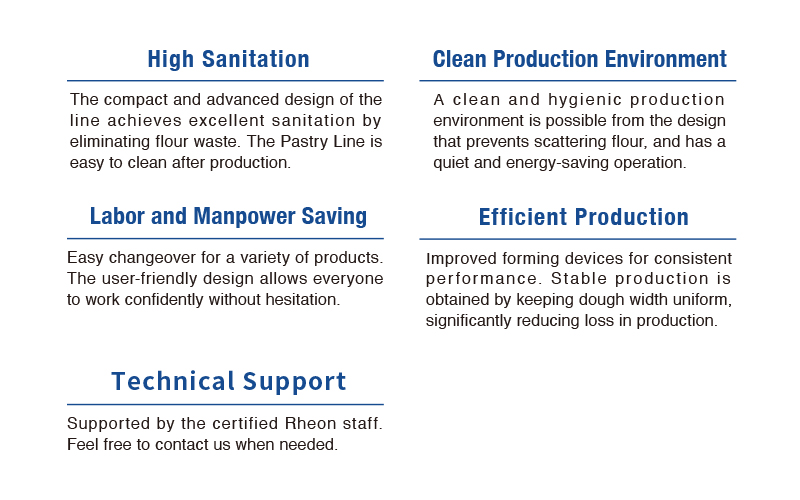

Features

Video

HM Pastry Line Key Features

New Multi-Stretcher: Damage-free dough stretching

One-box design frame covers forming section. No waste by preventing flour from scattering outside the stretcher. Automatic cleaning mode is added for stretching rollers. Excess flour on stretching rollers is cleaned automatically. Sanitation and safety are improved by maintaining high-performance stretching.

Inlet

Outlet

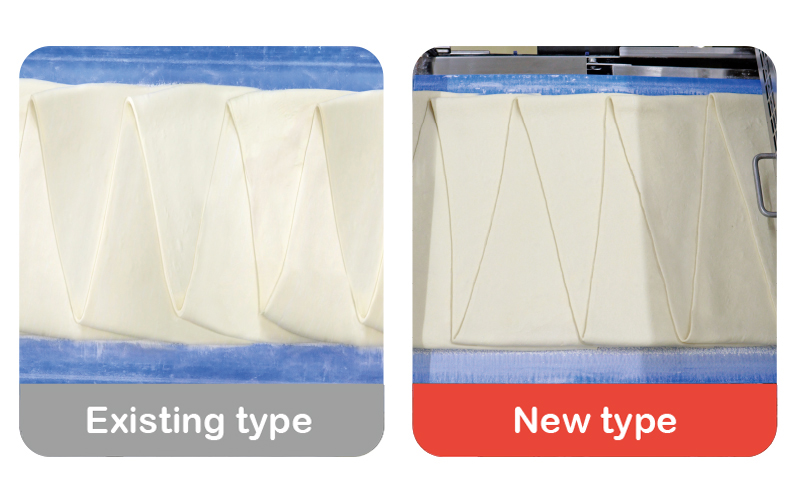

New Parallel Piler: Dough folding and layering

Keeps dough width uniform by reducing shrinkage of folded dough sheets.

Stable dough width minimizes trim loss. Uniform dough width improves weight accuracy.

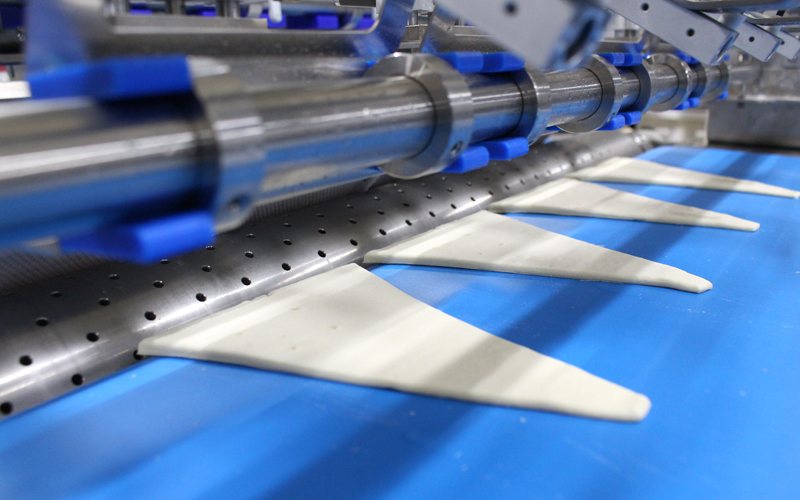

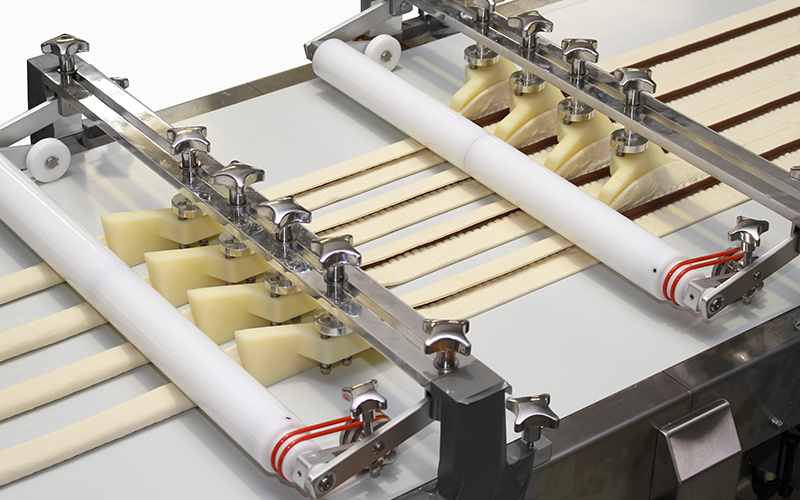

New Turner: Improved machine precision

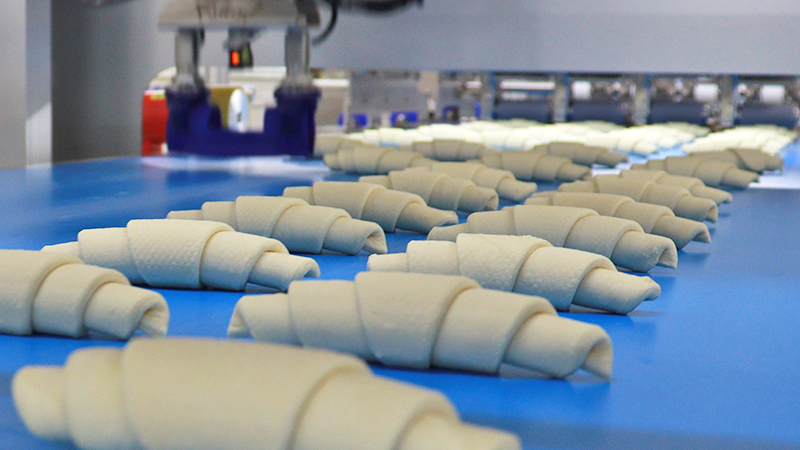

This device rotates dough cut into triangles, such as for croissants and butter rolls, 90 degrees. Sensors detect the dough and automatically adjust the movement and timing.

Improved accuracy with full 90-degree rotation of triangle dough sheet. Consistent production at 85 rpm (maximum speed) is available. Another turner is available for production in the range of 85 rpm-200 rpm.

New Molder: Flexible rolling control

The latest technology makes it easy to manage the degree of rolling and the final position of the rolling.

Vacuum Device* assists and improves the stability of rolling. (*This can be stored in the main body when not used.)

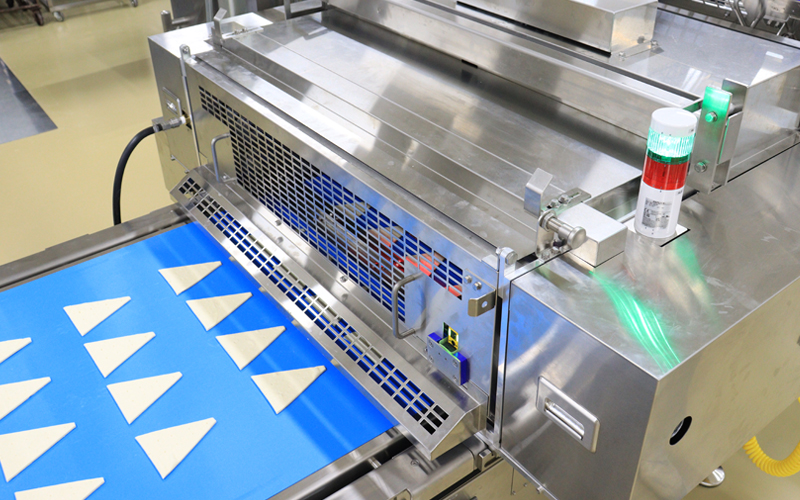

Variety Make-up Table with a number of potential arrangements

The Variety Make-up Table, which is attached to other machines, comes with a Double Rotary Cutter Frame that allows for up to two cutters to be attached; a Spot Spray that can be used in Spot, Continuous, or Drip modes; and a Scrap Conveyor that transports the excess dough created when adjusting dough width to the exterior, all as standard features. Its open underbody structure and easy-to-clean design allow for very hygienic use.

The various optional attachments can be smoothly interchanged.

IoT Function allows for visualization of free production

Visualizing Production! Operational and production parameters monitored daily. Visualize the status and error of each section of the line. Quick maintenance is available in cooperation with Rheon.

Introduction to various molding options

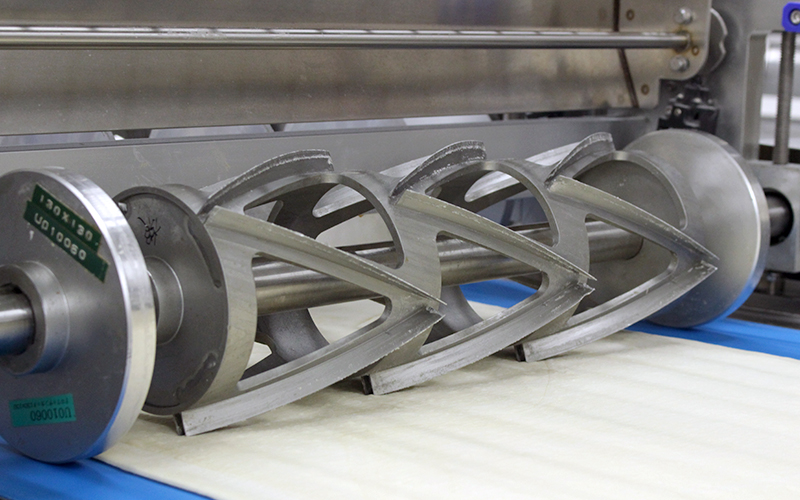

Various Rotary Cutter

The sheet-shaped dough is continuously cut into triangular, circular, and slit patterns using a rotating blade.

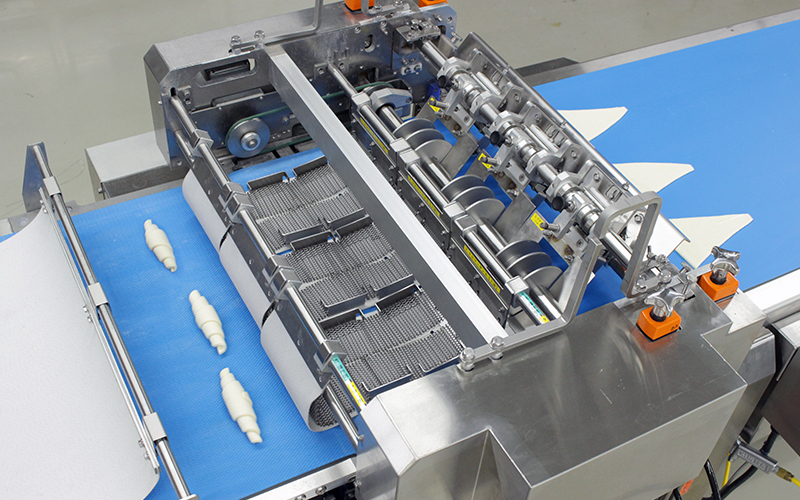

Croissant Turner

This is a device that changes the orientation of triangular dough by 90 degrees when making croissants and butter rolls.

Curling Unit

Automatically rolls up croissants and butter rolls. You can also roll up the dough tightly while pulling it.

Side Winder

The continuously flowing sheets of dough are rolled up by rotating rollers. It can be rolled up even with fillings or granular solid materials on top.

Folding Unit

This is a device that folds continuously flowing dough into two or three times using a turn guide.

Depositor

This is a device that dispenses ingredients such as bean paste, cream, and jam. We have a variety of equipment to suit different applications, including continuous dispensing, intermittent dispensing, and spot dispensing.